A commercial sow farm has two options when it comes to replacement gilts, the first is to raise them internally, and the second is to purchase them from another site or company. Producing replacements internally requires a very broad and intensive management style to effectively run two different populations within one farm. The other challenge is genetic improvement. If you don’t have the luxury of utilizing the best females for the purpose of replacement, it is very difficult to keep up with genetic progress.

Why do I need a healthy gilt source?

A multiplier is designed and focused on doing one thing well, making a top-notch replacement gilt. The objective starts with the end product – the market hog. With a healthy replacement female, farmers maximize performance by producing wean pigs that are high-performing, high-health animals, with a genetic makeup that provides for low mortality, efficient feed conversion, and fast growth. In short, a healthy gilt source ensures a wean-to-finish pig that is profitable.

A healthy gilt from a PIPESTONE managed multiplier is free of the heavy hitters of disease – Porcine Reproductive Respiratory Syndrome (PRRS), Porcine Epidemic Diarrhea (PED), Mycoplasma hyopneumonia, and carries high potential to be free of flu. In addition, the presence of secondary bugs like Streptococcus suis and Actinobacillus suis has been vastly minimized thanks to the diligent work of our vet team.

Impact

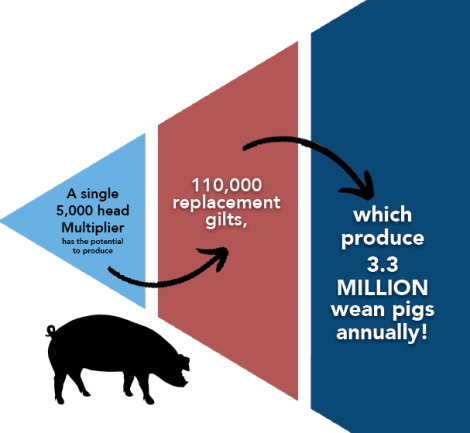

On average, a single gilt will produce more than 50 wean pigs in her lifetime. Multipliers have a major impact downstream. For example, a 5,000-head multiplier will provide approximately 110,000 replacements – supplying approximately 22 5,000-head commercial sow farms. Those replacements will yield nearly 3.3 million wean pigs for our shareholders – in just ONE year. All the more reason biosecurity is of the utmost importance at our multipliers.

Keys to Success

- Biosecurity

Multipliers follow the same biosecurity protocols as any commercial sow farm. However, in practice, these protocols are carried out more frequently and more intensely because the downstream implications of a health challenge are so vast. At each of our multipliers vet visits, testing, biosecurity and welfare audits, and employee training are carried out at least monthly, if not bi-weekly.Visitors, including PIPESTONE personnel, are required to have three nights away from pigs before they are allowed to shower in at a multiplier farm. All sites take note of proper D&D protocols, and each multiplier employs an office manager who provides our team with home-cooked meals to ensure no pork products are cooked on-site and ensures all areas inside the barns remain spotless. - Teamwork

If our multipliers are to be successful, the collaboration of our teams is vital. From construction and human resources to nutrition and transportation, a healthy gilt source is a direct result of our PIPESTONE family working in tandem. - Measurements

As multipliers have different roles in the supply chain, we measure success through four big areas – production performance, genetic improvement, product quality and downstream performance.

Production performance – we analyze a number of different metrics, but one that summarizes it best is pigs out the door. Our goal is for all multipliers to be weaning more than 13 pigs/sow and farrowing 102% of target.

Genetic improvement – multipliers place heavy consideration on two metrics at breeding time: pure line boar index and pure line sow index. To generate replacements of the highest genetic value, we only take the top 10% of the genetic sow indexing gilts to produce our replacements.

Product quality – the goal is to deliver a high-quality product to our clients: size matches with age, solid conformation, no physical defects, and external reproductive organs according to expectations (size of vulva, number of teats). Our goal is to have less than 1% of our animals rejected.

Downstream performance – final area to measure and quite honestly the most relevant is client satisfaction through analyzing product performance.

A healthy gilt source is not a new concept, in fact, it is the foundation on which Pipestone Management was built. Nearly 30 years ago, PIPESTONE built its first multiplier with the goal of providing family farmers access to healthy, replacement gilts.

Over the years, the focus of Pipestone Management shifted to commercial sow farms. Through research and work with commercial operations, we have proven just how much our biosecurity efforts pay off in helping to control the health of our pigs. Armed with the expertise of our team, PIPESTONE manages four multiplication farms located throughout the Midwest. If you are interested in learning more about gilt multiplication, contact Pipestone Management.

Article by Rodrigo Tueber

Article by Rodrigo Tueber

A veterinarian originally from Chile, Rodrigo started his career in the swine industry in 2004. He brought his knowledge and worldwide industry experience to PIPESTONE in 2021 and serves as the Director of Multiplication.